We are often asked by our customers- “Why it’s so expensive!? Other casts do much cheaper, and a copy – it’s a copy!”. In this review, we decided to describe in detail the process of our work on a miniature before it falls into your hands. Considering we will be a miniature Gryphon from the remarkable universe of Kingdom Death. So, let’s begin!

At first we debunk the delusion: Originals from the manufacturer very rarely are the standard of quality in themselves. The problem is that the sculptor, working on his master-model, made it like he wanted. But after the master-model falls into the hands of the organization, which has a contract for a certain, often a huge amount of goods. As a rule, in 90% of cases, this organization is located on the territory of China (So for the owner of the brand is cheaper). And accordingly the master-model of the Chinese employee is dismembered on an industrial scale (that is, several dozen pieces per day). We have nothing against our Chinese colleagues, but it’s like roulette is lucky / unlucky. After that, the parts of the master model are molded into silicone master molds (made in China naturally) and sent to the casting department. Then it’s all sent back to the brand owner and sold to you. Since the print editions are huge, and the resources of the matrixes are not unlimited, the quality of the finished miniatures is very rarely high. Because of this, already on the original miniatures very often we see bubbles, matrix displacements, lack of conjugation between parts, deformation. So, in fact, in 90% of cases, the so-called original miniature does not really differ much from what you buy from Chinese recasters on aliexpress, for example.

1) Nevertheless, we assume that for what we want to do, the original is as close to the ideal as possible. Here’s what the original Gryphon looks like on spare parts (Click on the picture to enlarge the image).

The gryphon photo on spare parts

2) Remove the burr (this is a completely standard procedure familiar to all collectors and players).

3) Further more difficult work: We need to remove the matrix displacements: the matrix shift photo. This procedure already requires some degree of skill from the person.

4) Straighten the deformed parts

5) If after these procedures we decide to assemble a miniature, we will get here such interesting gaps in the areas of conjugation of parts: several photographs of a fully assembled miniature with slits (Click on the picture to enlarge the image):

|

|

|

|

|

|

6) Our specialists carry out the procedure of perfect combination of surfaces with the help of putty and adjustments. This is the most difficult part of the work, since it requires high skill. Very often we have to literally sculpt again the missing pieces. That’s how Gryphon looks after our restoration work: photo conjugate parts (2-3 pcs) and the Gryphon himself close-up (Click on the picture to enlarge the image):

|

|

7) It is this sample WE consider the master-model and from it we make master forms. When manufacturing master forms, we use only high-quality silicone, but even it has a maximum of 20-25 castings. The damaged matrices are immediately replaced with new ones.

8) At the stage of obtaining already cast spare parts, we perform a thorough quality control and even the slightest deviations from our standards are not allowed. Epoxy resin, which we use is of high quality and has excellent physical and chemical properties: it is easy to dye, it is resistant to mechanical damage, it can withstand even short-term exposure to solvents (DO NOT ABUSE). And individual thin parts of miniatures that can break we reinforce a special wire!

9) After that, those parts that are recognized as meeting our standards are additionally cleaned from the burr, further order will be assmebled.

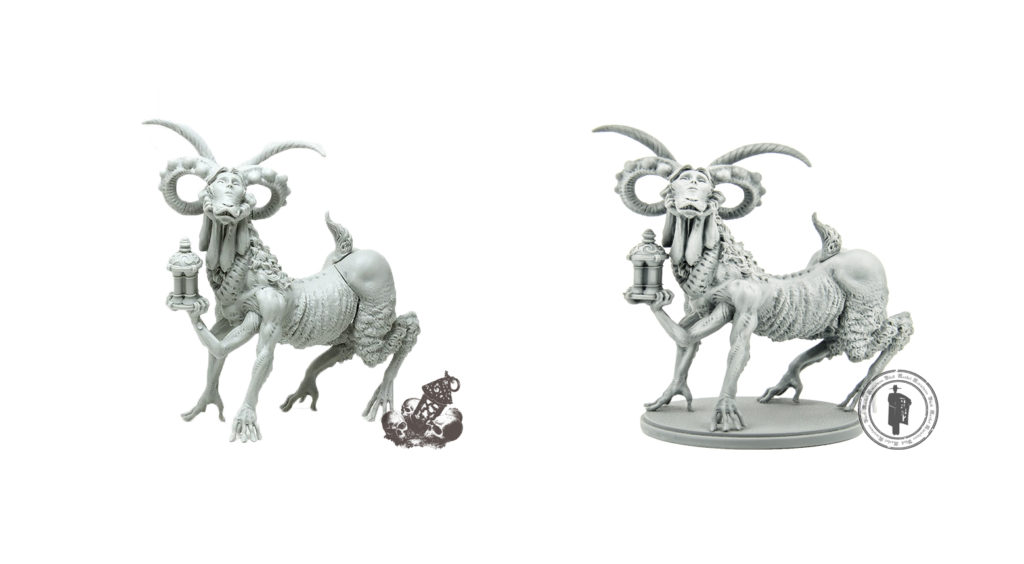

10) Thats look like finished miniature, which will please you in the future: a lot of photos that we usually post to the site (Click on the picture to enlarge the image):

|

|

|

|

|

|

|

|

|

|

In total, the restoration process, or Pro’Cast (as we call it), one miniature can take from a week to a month. In simple terms, instead of Chevrolet from the assembly line, you get a hand-assembled Ferrari. Whoever held the miniatures of our manufacture does not doubt this.

Due to the difficulty of restoring miniatures to the original state, the high cost of materials used and the abundance of highly skilled manual labor, our miniatures can not be cheap by definition. And in our case, you do not pay for the brand, not for marketing and not for the abundance of advertising, but for quality!

Therefore, we can rightly be proud of our product and our duty is to preserve and restore miniatures for our customers and fans of our creativity.

More examples of our work – the original photos from owner website (at the left) and our photo (right side) (Click on the picture to enlarge the image):

|

|

|

|